Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

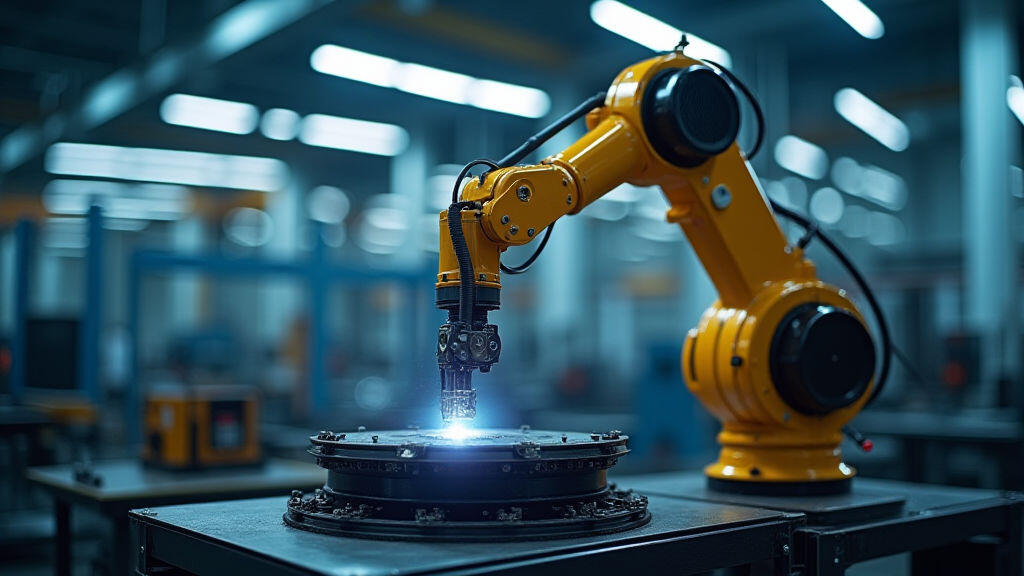

In early March this year, the International Federation of Robotics (IFR) released its annual robotics report, revealing a staggering 20 % year‑over‑year jump in the deployment of automated solutions worldwide. This surge, driven by AI‑enabled object recognition, cloud‑based workflow orchestration, and the relentless push for “smart factory” architectures, has captured headlines on CNBC, Bloomberg, and even on Twitter’s #Industry4.0 thread. The trend signals a turning point: factories are no longer beating metal and plastic, they are talking, learning, and adapting. What machinery lies at the heart of this metamorphosis? The humble yet mighty gear motor, also known as the reducer motor.

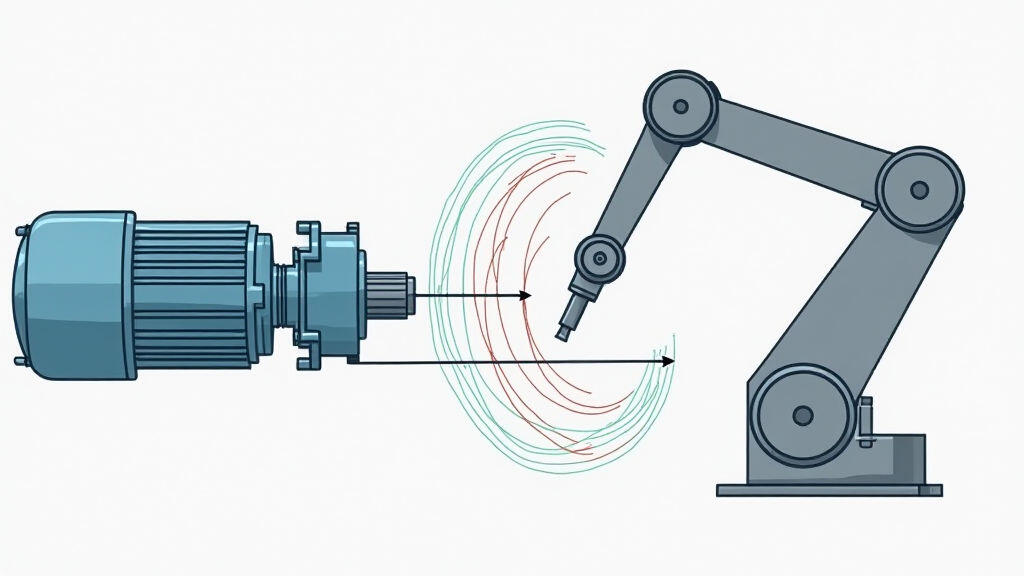

While AI algorithms shape decision‑making and data analytics, physical motion is governed by mechanical components. The gear motor—combining an electric motor with a gear reducer—translates electrical energy into smooth, high‑torque motion. It is the unsung workhorse that powers robotic arms, conveyor belts, CNC machines, and the smallest micro‑robots that perform dental surgeries. As Industry 4.0 pushes for faster cycle times, higher payloads, and lower energy consumption, gear motors are evolving in tandem to meet these unprecedented demands.

AI enables machines to see defects, predict failures, and adjust their behavior on the fly. However, these adjustments rely on rapid, precise mechanical execution. In an AI‑guided 3‑D printer, for example, micro‑millimeter positioning errors can ruin an entire build. Here is where gear motors shine:

Take the rollout of Tesla’s “Optimus” humanoid robot, for example. To match its 300‑lb payload and 2.0 m reach, the internal design calls for sub‑kilogram gear motors with torque outputs exceeding 120 N·m. Conventional motors simply cannot meet this specification without major size and weight penalties. Gear motors, therefore, become indispensable partners for realizing AI robots at scale.

The economic impact of AI‑driven automation extends beyond industrial plants. The same market forces are borne by burgeoning sectors such as autonomous agriculture, e‑mobility, and medical robotics. According to a recent McKinsey report, the global “smart factory” market is projected to grow from USD 95 billion in 2023 to USD 190 billion by 2028—implying a doubling of component orders each year.

Gear Motor OEMs have responded by offering:

Moreover, the industry’s pivot toward “edge AI”—executing inference locally within robots—has shortened feedback loops, demanding motors that can react within milliseconds. Integrated gear motors now feature embedded microcontrollers that can decouple speed or torque based on sensor input instantaneously, a crucial advantage in dynamic manufacturing environments.

Investments in research partnerships—between motor manufacturers and universities—drive innovations such as lightweight titanium gear teeth and advanced thermoelectric cooling. The International Organization for Standardization (ISO) has adopted new guidelines (ISO 18067) specifically for "gear motor performance in robotic applications," ensuring interoperability across international supply chains.

The push for reduced energy consumption—central to meeting Paris Agreement commitments—has dovetailed with the rise of gear motors. By integrating a high‑efficiency motor with a precision gear train, manufacturers can reduce power consumption by up to 40 % compared to obsolete rotary actuators. This not only cuts operating costs but also counters the carbon footprint of emerging technologies such as large‑scale aerial drones that rely on gear‑driven rotors.

Artificial Intelligence will soon move beyond control algorithms to predict motor wear, algorithmically adjust gear ratios in real time, and even self‑diagnose failures before they occur. Phased implementation of AI-driven torque maps inside gear motors promises to extend lifetime by 30 % and reduce maintenance hours by 25 %.

At the same time, the rising trend of “human‑robot collaboration” (c‑robots) means gear motors must offer tail‑fitting safety features, such as torque‑limiting mechanisms that automatically shut down if unexpected forces are detected. These safety features are being powered by real‑time AI sensors embedded in the robot’s joints, which instantly command the gear motor to rest.

The exploding popularity of AI‑enabled automation is not merely a story of software; it is equally a story of hardware that can keep pace with digital intelligence. Gear motors have risen to fulfill that role, offering the torque, precision, and adaptability required for the next generation of robots, conveyor systems, and manufacturing equipment. As factories worldwide strive to close the loop between data and motion, the gear motor stands ready as the engine that turns sparks of algorithmic thought into concrete, efficient action. The future of Industry 4.0—and every sector that adopts intelligent automation—depends on the relentless evolution of these indispensable components.

Leave A Reply

Your email address will not be published. Required fiels are marked